Assembly technology for a space deployable truss structure

The envisioned SSPS concepts have different configurations, operating orbits, and energy transmission methods. A large-scale SSPS must include a huge flat panel structure to generate and transmit power. In the SSPS model studied by METI, one of the 1-GW SSPS concepts, this will be achieved by connecting an array of flat “power generation/transmission panels” to form a huge square panel measuring 2 km per side. Each of the smaller panels making up the structure is composed of solar cells, microwave conversion circuits, and flat transmission antennas.

Image credit: J-spacesystems

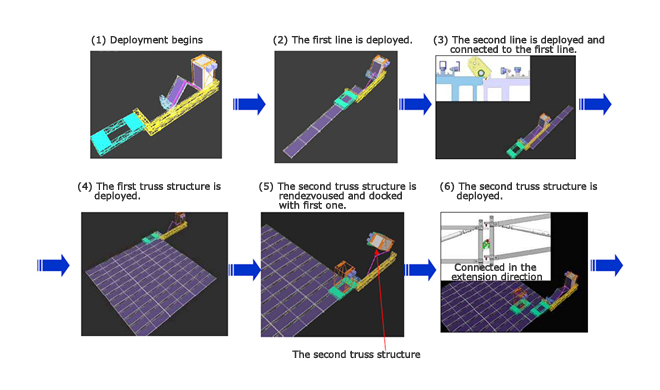

The SSPS Research Team has been researching a technology for the autonomous assembly of a deployable truss. The concept is to construct a large flat in-space structure by robotically deploying and connecting trusses in sequence. Each assembled truss structure would be rendezvoused and docked with other trusses orbited in a series of sequential operations to expand the overall configuration.

The team has been researching robotic assembly technology to build a 100-meter-scale space structure as a first step in its development research to realize this concept of autonomous assembly on the massive scale required.

Ground demonstration

The SSPS Research Team achieved promising results in the ground demonstrations it carried out in 2012 to assess the autonomous deployment and connecting function, a critical element of the technology for assembling the deployable truss structure. Our next steps will be a series of sequential assembly demonstrations for the docking members of other parts of the system.

The system is designed to demonstrate a technology for robotically assembling a 100-meter-scale space structure (deployable truss assembly technology). A deployable truss and assembly device (silver-color) are supported by hanging hardware (suspended from a blue frame) to cancel gravity.

Technological challenges

The following technological issues entailed in this large structure assembly technology will have to be solved in ensuing months and years. In parallel, studies will also be conducted on assembly methods incorporating innovative technologies and ideas.

- Avoidance of undesirable configurations during assembly, attitude/orbit control

- Compensation for thermal distortion

- Maintenance, disassembly