An example of research results

Research and Development of Dust Seals for Main Spindles

We are researching and developing several types of seals for use where reliable sealing is required, such as the drive shaft of a rover. One of these seals is a mechanical seal.

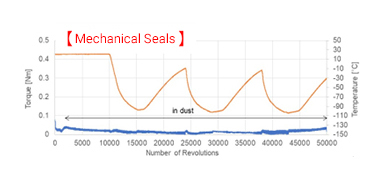

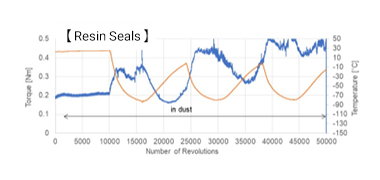

We select and develop materials and coatings that are hard and have low coefficients of friction so that regolith does not wear rover parts or cause seal performance to be lost when it enters the sealing surface between the rotating shaft and a fixed part. In addition, the pressing force and materials are optimized so that the force required for rotation is as low as possible while maintaining sealing performance. Figure 2 shows the torque transition in a vacuum dust environment while changing the temperature to the low-temperature side. Compared to the resin seals normally used, the torque remains low and unaffected by temperature. No dust ingress was observed after the test.

Research and development of dust seals for bearings

We are researching two types of simple bearing seals that come into direct contact with regolith: one using a ring-shaped collar and the other made of a felt material. For the collar seal, we have designed a shape that allows the collar to hold and seal the bearing firmly at the end face and optimize the pressing force. The felt seal is a new attempt to use felt material for space applications. It rotates with less resistance while ensuring high sealing performance.